Large. Asymmetrical.Extreme.

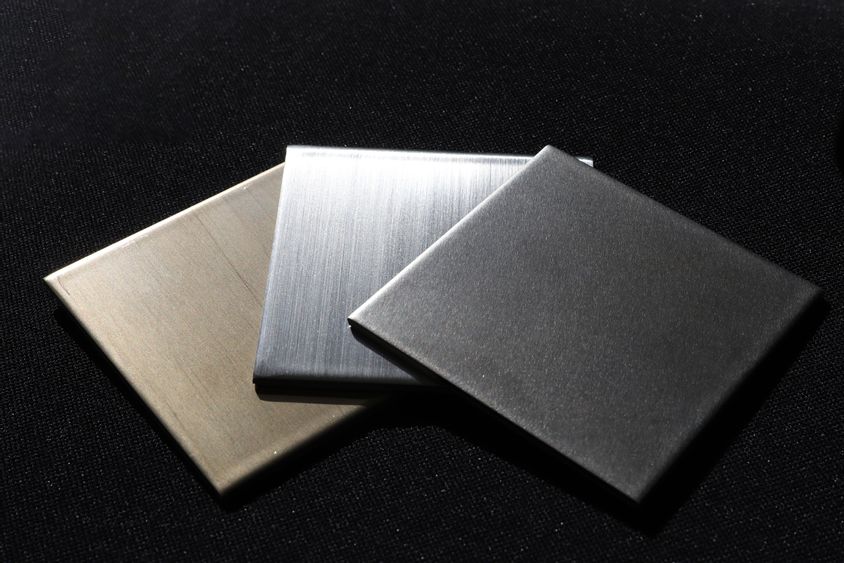

At Rieber we are specialised in deep-drawing special sheets, minimal sheet thicknesses or sandwich materials.

01 Deep drawing with tools

Deep drawing - form and counter formHighly modern, CNC-controlled, hydraulic presses from 30 t up to 2000 t pressing force are available in our machine park. Our technology also allows us to produce large-area, asymmetrical and extremely deformed components. The deep-drawn part is the result of a precisely calculated and simulatable production process in which the deep-drawing and annealing steps can alternate repeatedly.

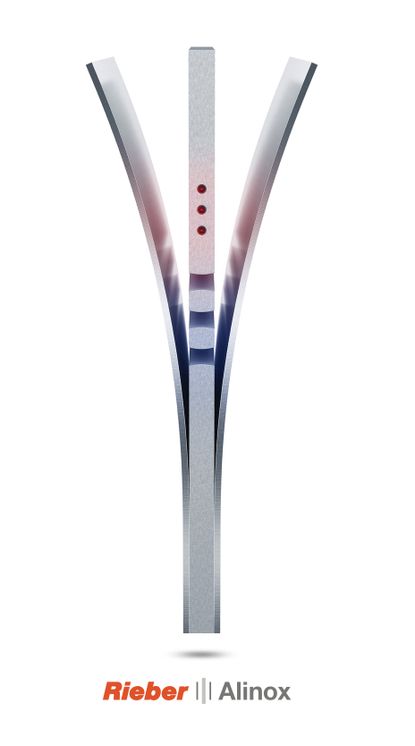

02 Hydromechanical deep drawing

Deep drawing with water cushionA variation of the classic drawing process is hydromechanical deep drawing. A pressure-regulated water cushion replaces the die. The sinking punch of the upper part of the tool presses the sheet metal blank against a water cushion, pulling it along with it as it is immersed, thus applying exactly the desired geometry to the drawn part.

Due to the distributed pressing of the sheet metal against the punch by the die medium, the position of the critical drawing area shifts from the bottom of the workpiece to the drawing radius. Therefore, higher drawing ratios can be realised than with the classic drawing process, and this at lower manufacturing costs due to the relatively small installation space.